Dispense Robots and Sealing Robots

For robotic assembly applications involving dispensing and sealing, cobots (collaborative robots) are becoming the go-to solution. Dispensing and sealing robots allow for volumes and rates to vary widely, from small syringe applicators to large volume, dual-drum, automatic switchover units.

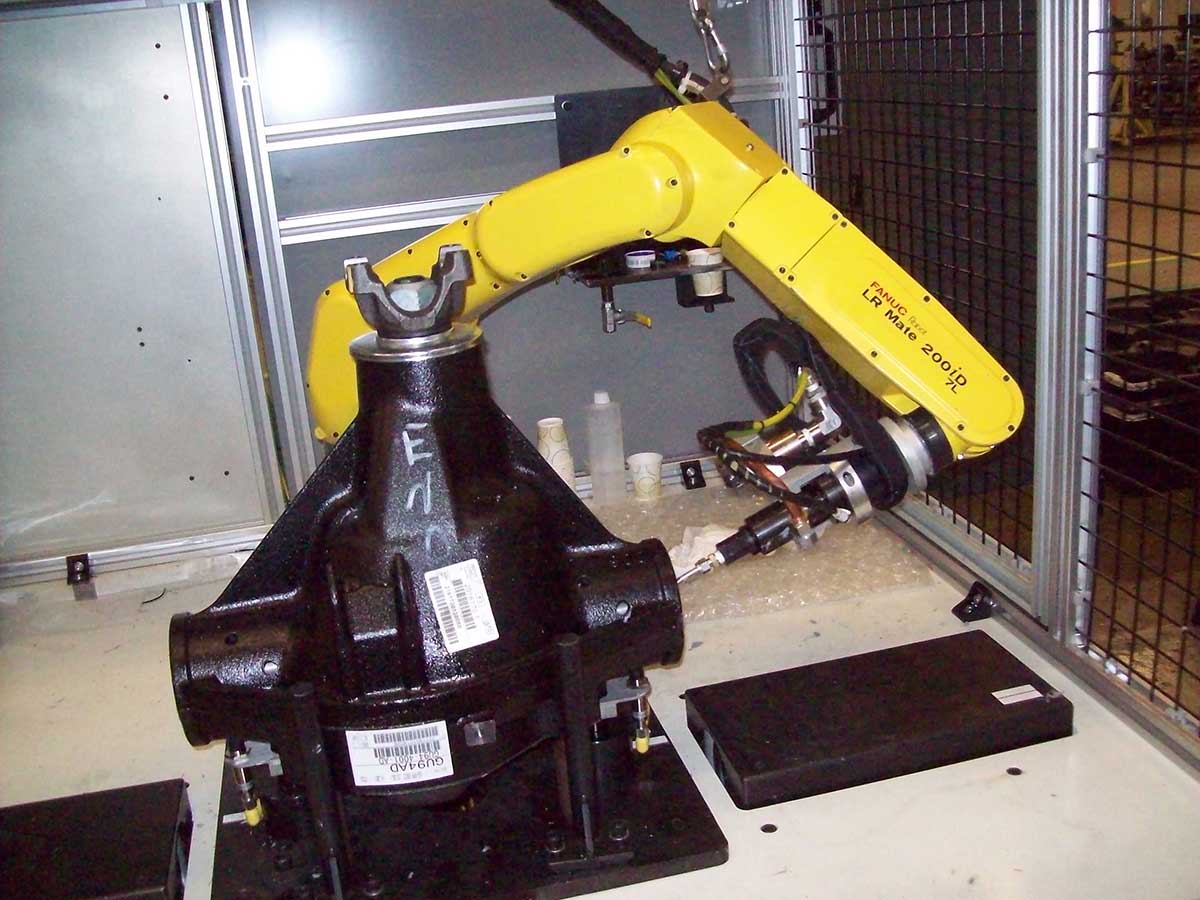

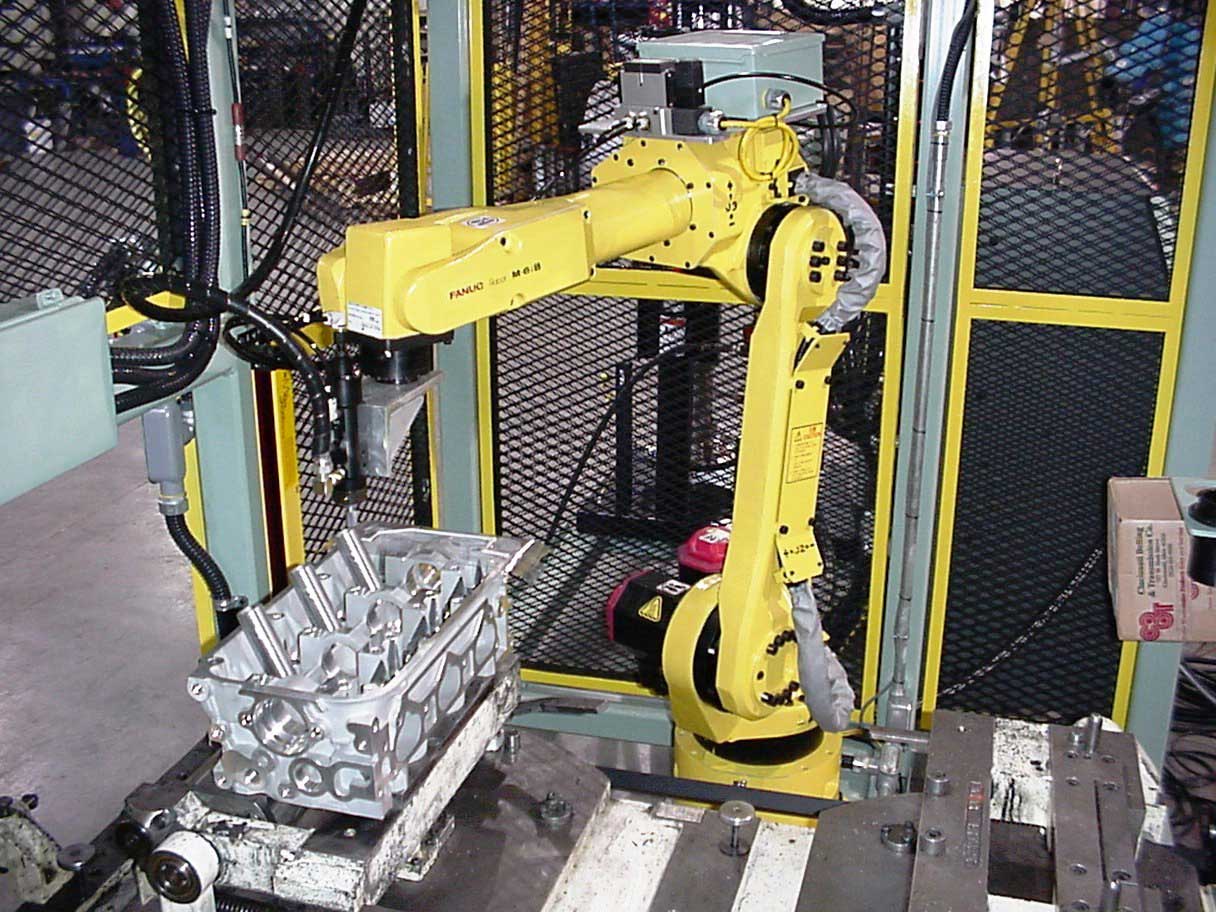

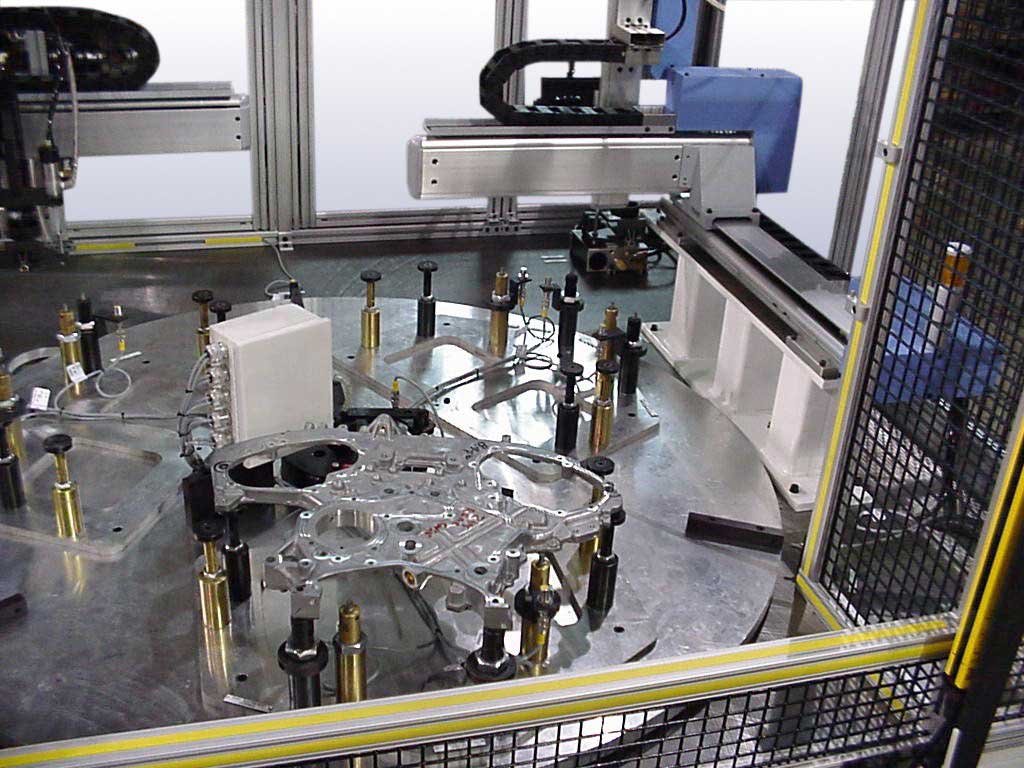

A dispensing and sealing robotic system consists of three main components: part fixturing, material supply, and robotic applicators. Robots can be configured to present the part to a dispensing valve, or they can move a dispensing valve over the face of the part. They are traditionally cartesian (linear) or scara robots for flat applications and six-axis, articulated-arm robots for 3D applications.

How Dispensing & Sealing Robots Improve Processes

Dispensing and sealing robots can be stand-alone systems or part of a larger process. They are commonly used for the application of:

- Adhesives

- Form in Place Gasket (FIPG) Materials

- Insulating Materials

- Grease

- Sealants

- Masking Materials

Traditional manual application methods have many drawbacks, such as inaccuracy and misalignment, which can lead to poor quality seals and adhesion, or improper fixturing. Inconsistency in the amount of material applied can also create problems. Too little adhesive material can lead to poor joints or seals, while too much can be costly and lead to assembly issues.

Robotic application offers several advantages including consistent bead size, proper bead path location, and elimination of material gaps. Robotic dispensing and sealing offer high quality, highly repeatable results.

Industries that Benefit from Dispensing & Sealing Robots

- Automotive

- Transportation

- Aerospace

- Consumer Products

- Life Sciences

- Packaging

Why Choose Remtec?

As one of the leading robotic integrators in North America, Remtec has assisted a wide range of manufacturing organizations with dispensing and sealing robotic solutions. As your robotic automation partner, Remtec offers you the benefits of:

- Years of experience in automotive and consumer products applications

- Extensive installed base of equipment for dispensing grease, FIPG, paint, and adhesives

- Low and high volume system experience

- Development of both stand-alone systems and systems integrated over existing production lines

- Ability to customize our platforms to suit the end user’s requirements

- We will work with your preferred material supplier to specify the equipment required to automate your process

- Vision inspection options for bead skip and bead detect quality enhancement

For customers who are new to robotics, we work with you to make the integration process easy and accessible. From employee robot training to user-friendly traditional HMI based controls, we make transitioning to robotic automation as smooth and simple as possible.