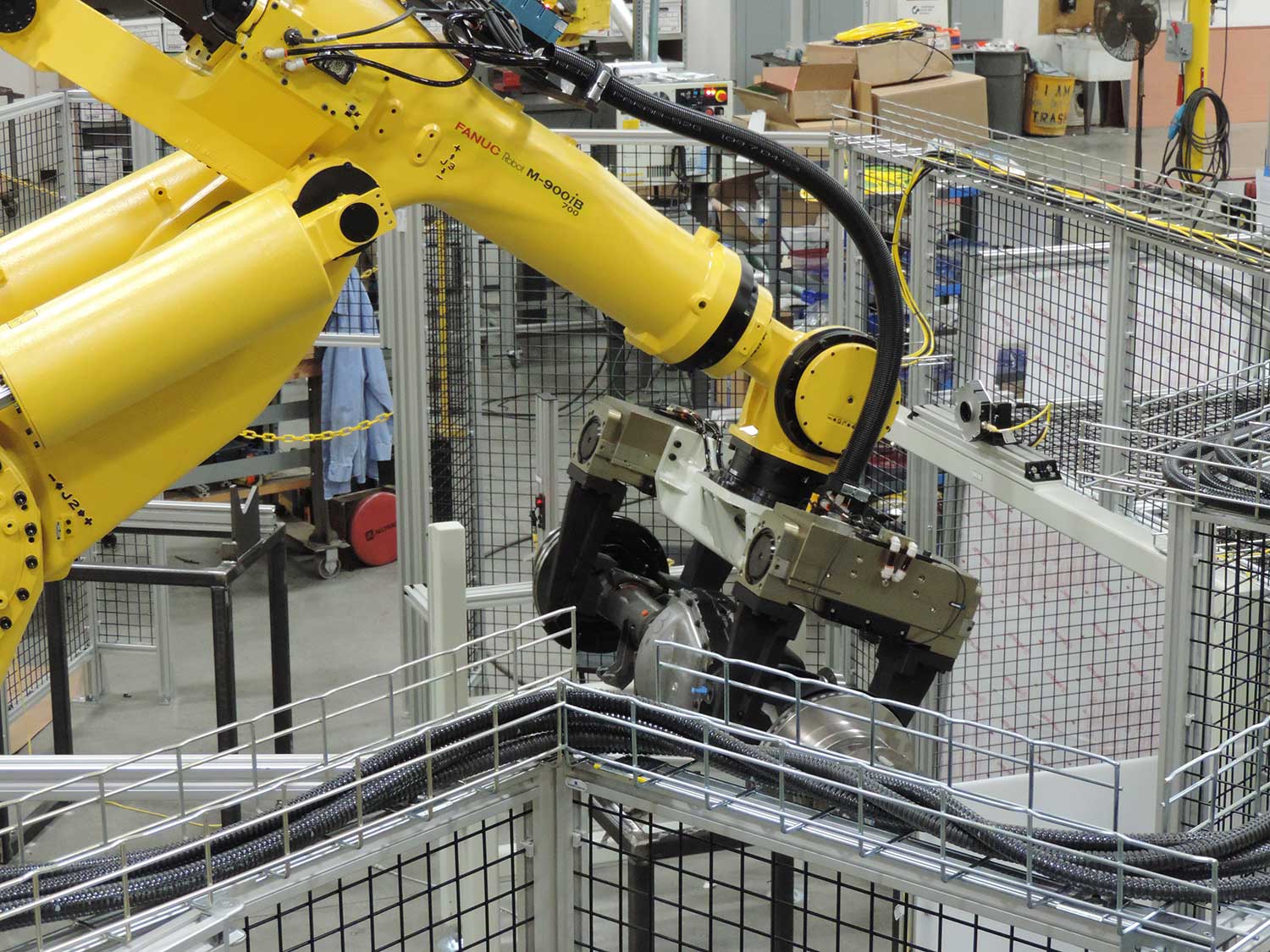

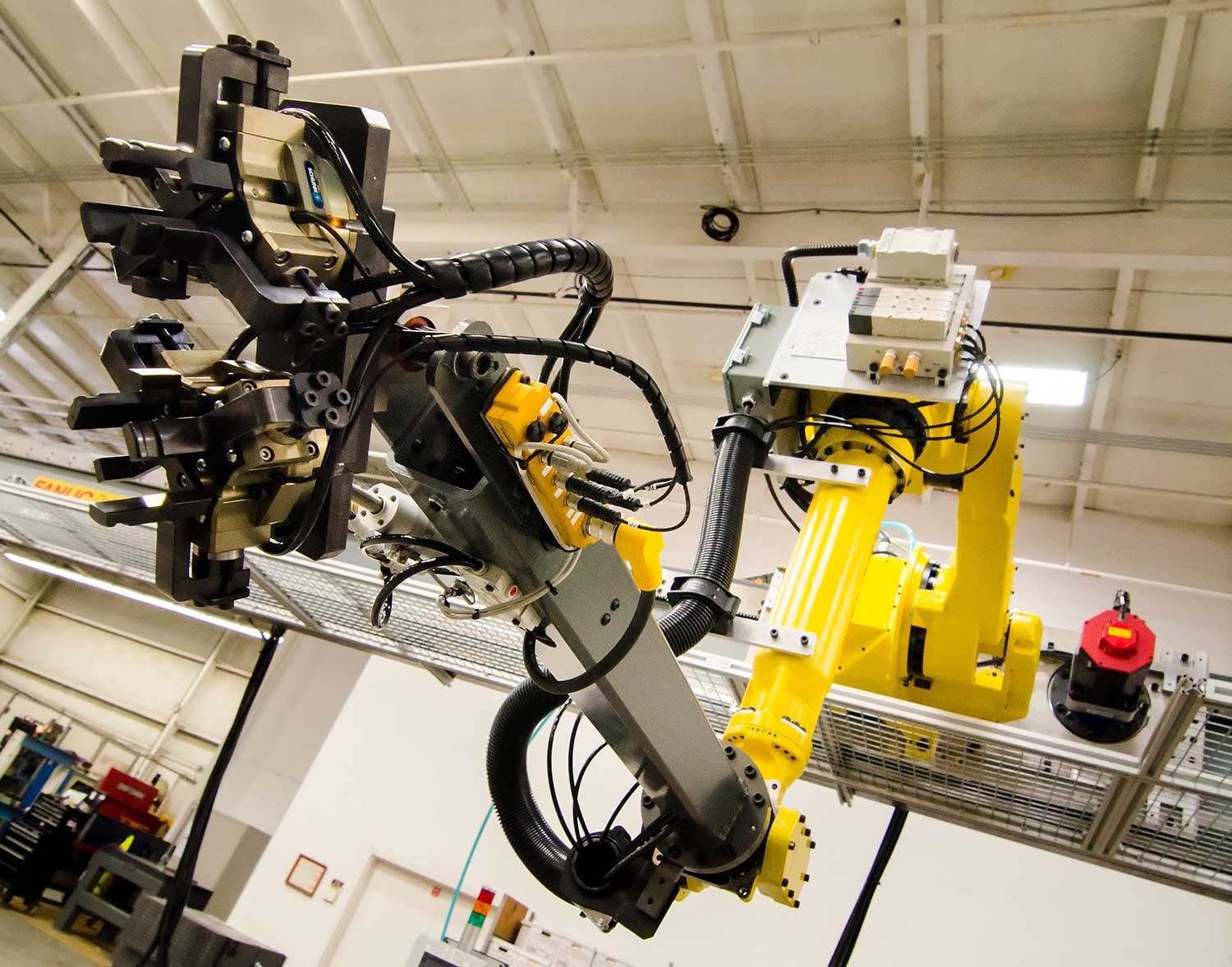

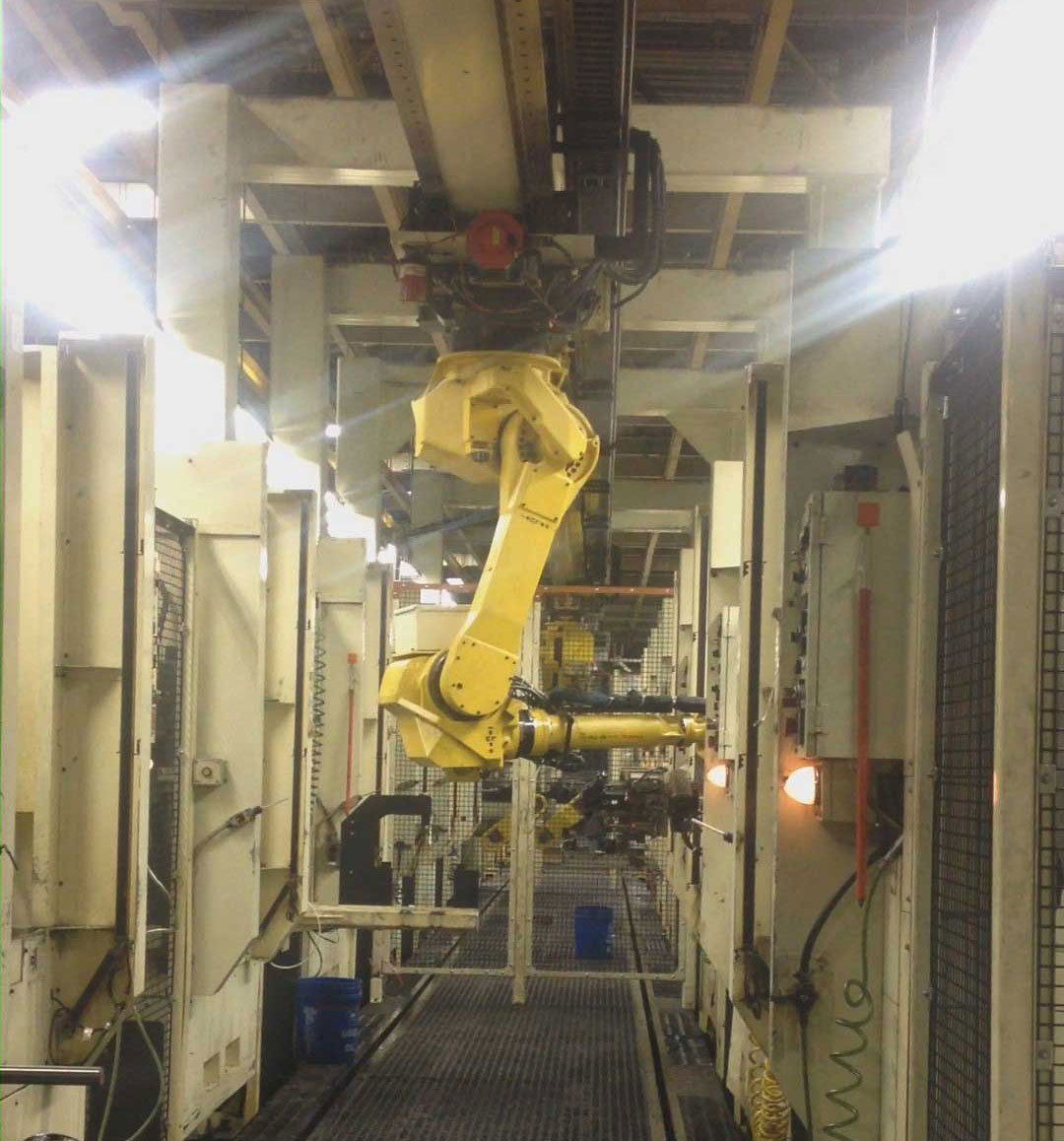

Machine Tending Robots

One of the most important advantages of robotic automation is relieving employees of repetitive tasks that put them at risk for accidents and injuries. Machine tending robots are especially suited for these types of tasks.

Examples include loading and unloading parts from CNC mills, machining centers, lathes, presses, and injection molding machines. In many cases, they transfer parts directly between processes, conveyors, automated guided vehicles (AGVs), or work in progress (WIP) queues.

Benefits of Machine Tending Robots

As noted, relieving operators from potentially hazardous or injurious repetitive manual tasks is a significant benefit of using robotic automation. Costly manufacturing issues involving problems with machine utilization, throughput, and quality can also be resolved with machine tending robots. All of these considerations can be improved with automation:

- Robots take the repetitive motion away from an operator, which leads to fewer injuries

- Time needed to load and unload parts from a machine is reduced, so more parts can be manufactured in a shift, increasing the capacity of existing production lines

- Robots enhance production by providing secondary line operations, such as material removal, pre and post injection molding, dispensing, and assembly

- Robots load parts consistently, which improves the quality of the machining operation and lessens the amount of scrap material

Industries that Benefit from Machine Tending Robots

- Automotive

- Transportation

- Aerospace

- Plastics

Why Choose Remtec?

As one of the leading robotic integrators in North America, Remtec has improved the efficiency and profitability of many manufacturing operations with machine tending robotic solutions. As your robotic automation partner, Remtec offers you the benefits of:

- Years of experience in automotive and consumer products applications

- Low and high volume system experience

- Ability to customize our platforms to suit the end user’s requirements

- Will work with your preferred material supplier to specify the equipment needed

- Vision inspection and gauging options for quality checks at each machine

- Systems for part and process traceability

- System customization for the end-user’s unique processes

Remtec offers you the benefit of extensive experience in the development of machine tending robotic applications. We work hard to identify the most efficient and cost-effective equipment to achieve your process goals while staying within the scope of your budget. Remtec also develops a thorough cost/benefit analysis for your team to see the justification for your robotic automation investment.

If you are new to robotics, we will work with your company to make the integration process easy and accessible. From employee robot training to user-friendly traditional HMI based controls, we make transitioning to robotic automation as seamless as possible.