The Financial Benefits of Implementing Robotic Palletizing

When considering ways to improve the efficiency and profitability of your business, have you examined your palletizing operations? While traditional manual palletizing methods tend to be labor-intensive, prone to error and often lead to workplace injuries, robotic palletizing solutions offer a compelling alternative. Read on as we explore the drawbacks of conventional palletizing methods and … Continued

Six Reasons to Choose a Certified Vision Specialist for Your Machine Vision Integrator

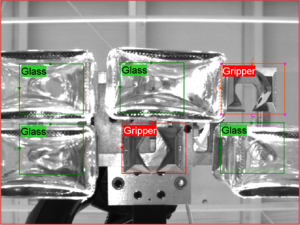

In today’s rapidly evolving technology-driven workplace, machine vision has become increasingly advantageous across a wide range of industries. From quality control in manufacturing to autonomous vehicles and medical imaging, machine vision systems play an essential role in enhancing efficiency, accuracy, and productivity.

The successful implementation of such systems hinges upon partnering with the right integrator, preferably a Certified Vision Specialist.

3 Ways that Cobots Work in Material Handling & Process Applications

The integration of automation has become indispensable. Cobots, or collaborative robots, have emerged as a game-changer, particularly in material handling and process applications. These versatile machines work alongside human workers, enhancing efficiency, safety, and productivity. Read on to take a look at three key ways cobots are reshaping these sectors: vision inspection, dispensing, and palletizing.

Optimizing Manufacturing Efficiency: A Guide to Effectively Integrating Robotic Palletizers

Benefits of Working with a Fanuc Authorized System Integrator

Understanding Digital Twinning and Simulation in Robotics

Lighting Challenges in Robotic Machine Vision Applications

Case Study: S.S. White Technologies Vertical Pouch Process Benefits from Robotic Automation

C.M. Paula and Remtec Automation Headquarters Expansion Is Complete

Case Study: Hartz Mountain Blister Packing Process Benefits from Robotic Automation

Hartz Mountain was experiencing labor shortage problems, with a specific need for operators to load tubes of product into their blister seal packaging machines. Read more to learn how the Remtec team was able to develop an automated robotic system to meet the customer’s blister packing process needs.