3 Ways that Cobots Work in Material Handling & Process Applications

The merging of today’s industrial and technological landscapes is rapidly evolving. The integration of automation has become indispensable.

Cobots, or collaborative robots, have emerged as a game-changer, particularly in material handling and process applications. These versatile machines work alongside human workers, enhancing efficiency, safety, and productivity. In this post, we will look at three key ways cobots are reshaping these sectors: vision inspection, dispensing, and palletizing.

1. Vision Inspection

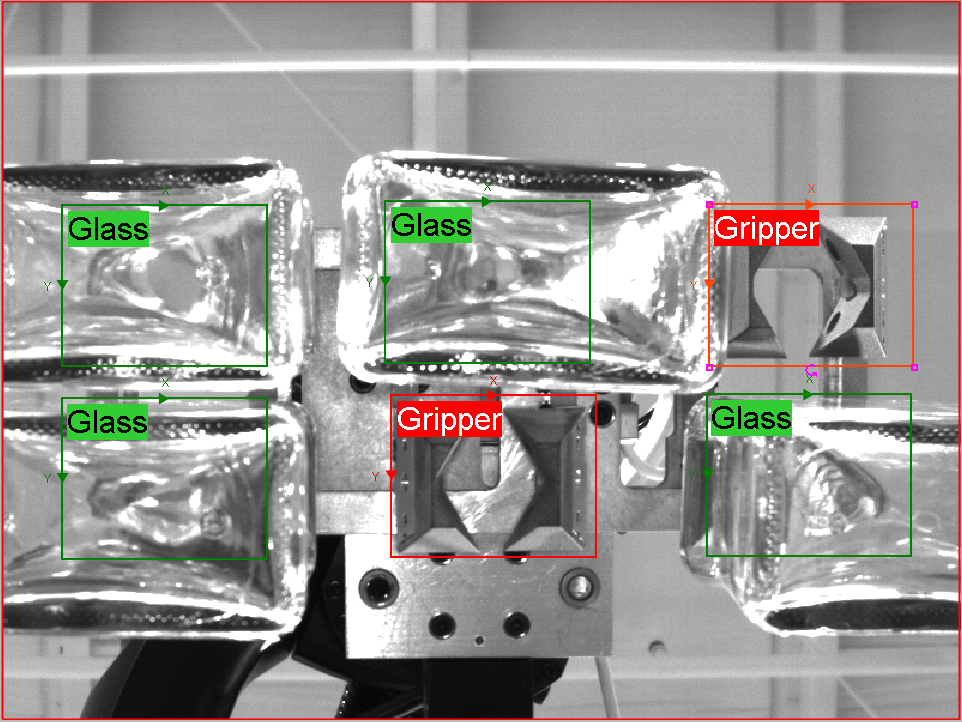

Vision inspection takes maintaining product quality to the next level, providing a dependable way for companies to ensure compliance with stringent industry standards. Traditionally, human operators have been tasked with visually inspecting products, a process prone to errors and inconsistencies. However, with the advent of cobots equipped with advanced vision systems, this has become exponentially more efficient and reliable.

Cobots are integrated with high-resolution cameras and sophisticated algorithms capable of analyzing intricate details with precision. In material handling, cobots can inspect products for defects, irregularities, or anomalies in real-time, significantly reducing the likelihood of faulty products reaching the market. Vision inspection cobots offer flexibility with the ability to seamlessly adapt to various product shapes, sizes, and textures, offering unparalleled flexibility and accuracy.

By automating vision inspection processes, companies can streamline quality control, minimize production downtime, and ultimately enhance customer satisfaction. Cobots not only improve efficiency but also alleviate the burden on human workers, allowing them to focus on more complex tasks that require creativity and problem-solving skills.

2. Dispensing

Dispensing tasks, such as applying adhesives, sealants, or coatings, are required in numerous manufacturing processes. Traditionally, these tasks have been performed manually, presenting challenges in consistency, precision, and worker safety. Cobots equipped with dispensing capabilities offer an effective solution to address these issues.

With advanced programming and precise control, cobots can dispense materials with unparalleled accuracy and repeatability. Whether it’s applying adhesive beads with submillimeter-level repeatability or coating intricate components uniformly, cobots excel in maintaining consistent quality throughout the production process.

An additional advantage of cobots is that they enhance workplace safety by minimizing human exposure to hazardous materials. They also reduce the risk of repetitive strain injuries associated with manual labor dispensing tasks. By automating dispensing processes, companies can optimize material usage, reduce waste, and achieve higher throughput rates, ultimately driving cost savings and competitive advantage.

3. Palletizing

Palletizing, the process of stacking and arranging products onto pallets for storage or shipping, is a labor-intensive process which is usually performed by people. These processes are inherently hazardous for humans, particularly when performed repeatedly, over extended periods of time.

Using cobots equipped with specialized end-of-arm tools and advanced motion planning algorithms provides relief for employees who have had to allocate much or all of their work day to these tasks. Collaborative robots can efficiently handle a wide range of products, stacking them with precision and speed. Moreover, cobots can adapt to dynamic environments, adjusting pallet configurations on the fly to accommodate varying product dimensions and stacking patterns.

By automating palletizing tasks, companies can optimize warehouse operations and efficiency while increasing throughput rates. As an added advantage, cobots allow for scalability, offering businesses a way to easily adjust production volumes to meet fluctuating demand with minimal disruption and expense.

Remtec is Your Reliable Source for Robotic Automation Integration

Remtec is an experienced robotic automation integrator with expertise in cobot systems. Our team of engineers will evaluate your existing production process to get the most from existing assets while integrating new technologies to move your operation to the next level.

We use the latest analysis and simulation tools to model your existing process. We then design, deliver, and install a complete robotic integration system, completely integrating all processes including: cobot vision inspection, dispensing, palletizing, and more.

Remtec’s robotic integration experience translates to your competitive advantage. Contact us to discuss how Remtec can help you advance your business through robotic automation.